PERI GmbH is building Germany’s first 3D-printed residential building in Beckum, North Rhine-Westphalia. The two-storey detached house with approximately 80 square meters of living space per floor is not being constructed in the conventional manner, it is being printed by a 3D construction printer.

This construction technique, which is being put into practice in Germany for the first time, has come through all of the regulatory approval processes over the last few weeks and months. The engineering office Schießl Gehlen Sodeikat supported the development of the concept for obtaining the approval, the planning and execution of the corresponding approval tests was carried out by the Technical University of Munich.The building was planned by MENSE-KORTE ingenieure+architekten and the client is Hous3Druck GmbH. The materials used to produce the printable concrete are being sourced from HeidelbergCement.

The federal state of North Rhine-Westphalia is supporting the 3D construction printing project in Beckum as part of its “Innovatives Bauen” development scheme.

The building was planned by MENSE-KORTE ingenieure+architekten and the client is Hous3Druck GmbH.

PERI uses 3D printers of type BOD2 for printing. This printing technology comes from the Danish manufacturer COBOD. PERI acquired a stake in COBOD back in 2018. The BOD2 printer used in Beckum is a gantry printer, which means that the print head moves about 3 axes on a securely installed metallic frame. The benefit here is that the printer can move along its frame to any position within the construction and only needs to be calibrated once.

The “i.tech 3D” material used in the printing process was developed by HeidelbergCement specifically for 3D printing. Its properties are tailored to the specific requirements of 3D construction printing and it works perfectly with the BOD2 printer. This ensures that consistent progress is made throughout the construction project.

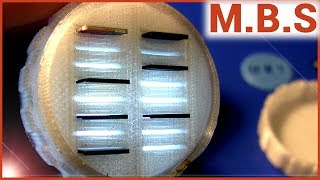

The building consists of triple-skin cavity walls, which are filled with an insulating compound. During the printing process, the printer takes into account the pipes and connections for water, electricity, etc. that are to be laid at a later time. The BOD2 has been certified in such a way that it is possible to carry out work within the printing area while printing is in progress. This means that manual work, such as the installation of empty pipes and connections, can be easily integrated into the printing process.

Only two operators are required to run the printer. The print head and the print results are monitored by a camera. With a speed of 1 meters per second, the BOD2 is currently the fastest 3D construction printer available on the market. The BOD2 only takes around 5 minutes to complete one square meter of a double-skin wall.

#ConstructionNews #InfrastructureNews #SteelGuruBusinessNews #OnlineNews #BusinessNews

This construction technique, which is being put into practice in Germany for the first time, has come through all of the regulatory approval processes over the last few weeks and months. The engineering office Schießl Gehlen Sodeikat supported the development of the concept for obtaining the approval, the planning and execution of the corresponding approval tests was carried out by the Technical University of Munich.The building was planned by MENSE-KORTE ingenieure+architekten and the client is Hous3Druck GmbH. The materials used to produce the printable concrete are being sourced from HeidelbergCement.

The federal state of North Rhine-Westphalia is supporting the 3D construction printing project in Beckum as part of its “Innovatives Bauen” development scheme.

The building was planned by MENSE-KORTE ingenieure+architekten and the client is Hous3Druck GmbH.

PERI uses 3D printers of type BOD2 for printing. This printing technology comes from the Danish manufacturer COBOD. PERI acquired a stake in COBOD back in 2018. The BOD2 printer used in Beckum is a gantry printer, which means that the print head moves about 3 axes on a securely installed metallic frame. The benefit here is that the printer can move along its frame to any position within the construction and only needs to be calibrated once.

The “i.tech 3D” material used in the printing process was developed by HeidelbergCement specifically for 3D printing. Its properties are tailored to the specific requirements of 3D construction printing and it works perfectly with the BOD2 printer. This ensures that consistent progress is made throughout the construction project.

The building consists of triple-skin cavity walls, which are filled with an insulating compound. During the printing process, the printer takes into account the pipes and connections for water, electricity, etc. that are to be laid at a later time. The BOD2 has been certified in such a way that it is possible to carry out work within the printing area while printing is in progress. This means that manual work, such as the installation of empty pipes and connections, can be easily integrated into the printing process.

Only two operators are required to run the printer. The print head and the print results are monitored by a camera. With a speed of 1 meters per second, the BOD2 is currently the fastest 3D construction printer available on the market. The BOD2 only takes around 5 minutes to complete one square meter of a double-skin wall.

#ConstructionNews #InfrastructureNews #SteelGuruBusinessNews #OnlineNews #BusinessNews

- Категория

- Новости 3D Печати

Комментариев нет.